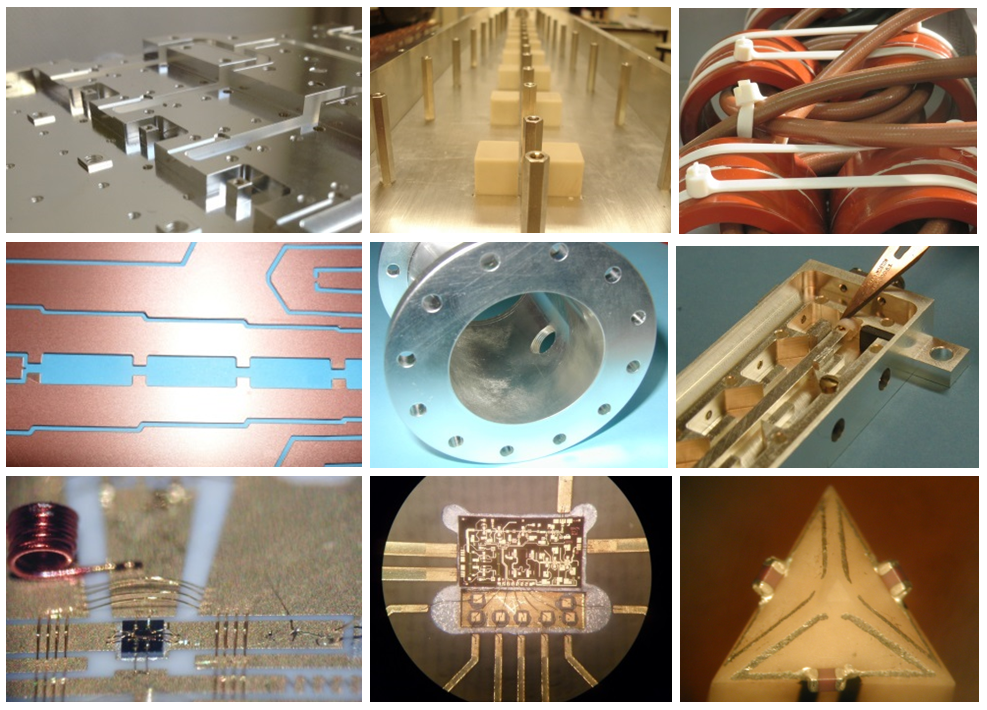

Design is the heart of our activity and we consider it like a technical art.

Committed to satisfying our customers’ issues and challenges, we do our best to quickly deliver efficient and fully tailored designs.

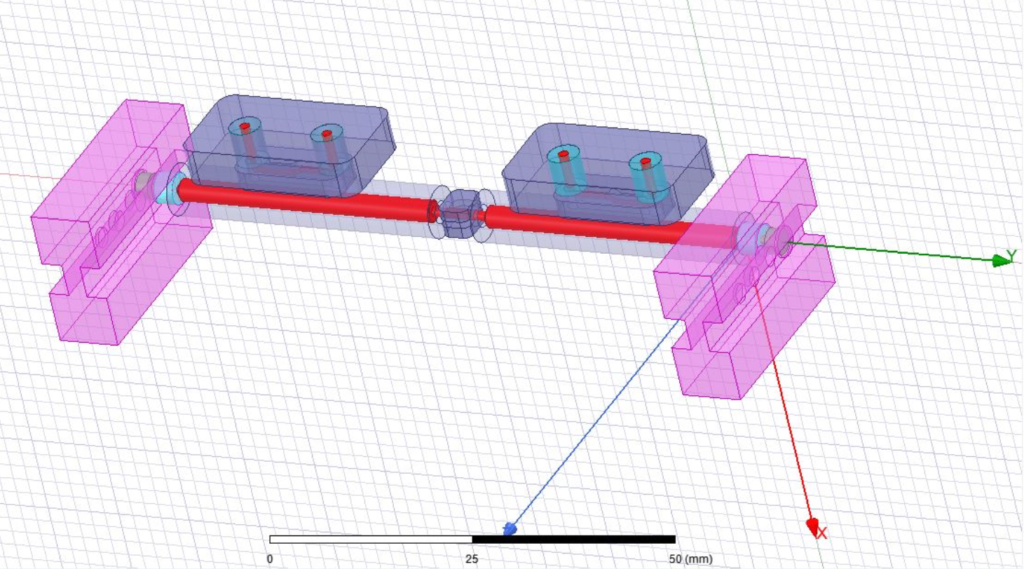

To make this possible, we continuously invest in powerful workstations equipped with up-dated simulation and modeling software :

We combine our modelling and simulation expertise with our mastery of advanced and cutting-edge technologies to offer our customers the most efficient solutions at cost-effective.

- Electromagnetic simulation software: Ansoft HFSS, Ansoft Designer, Ansoft Optimetrics,

- In-House Engineering Simulation Tools

- Solid Edge 3D CAD software

- Calculation and programming software

- Genesys RF and microwave design software

- PCB design software